Electric Materials Company

Electric Materials is a premier North America’s manufacturer of high-quality electrical grade copper and fabricated copper components since 1915. We produce extrusions, castings, forgings, finished parts, and fully assembled commutators. Our products are sold around the globe and service power distribution, power generation, mining, industrial, nuclear markets among many others. Our impressive 426,000 sq. ft plant in North East, PA employs over 200 workers and houses best-in-class 20’ fully automated plating line and full CNC machining and fabricating capabilities designed to meet most demanding customer specifications.

814.725.9621

Electric Materials Services

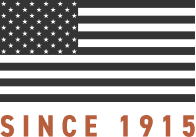

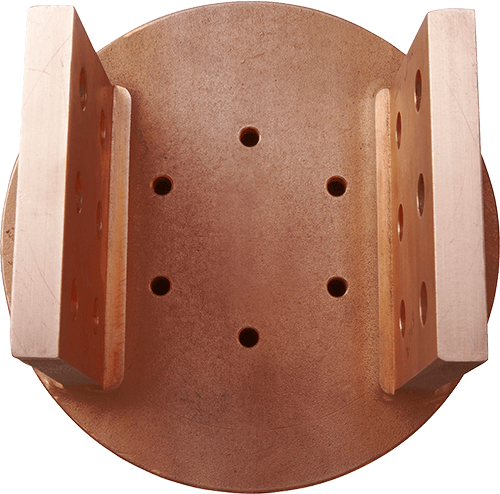

Commutator Manufacturing

Electric Materials is a global leader in commutator manufacturing. Our expertise is recognized among transportation leaders, and our commutators are in service in some of the most demanding applications and harshest environments on earth. With complete start-to-finish commutator manufacturing capabilities, we provide a variety of clients with high-quality OEM commutators, rebuilt commutators, and rotor bars. Electric Materials expertise include:

- Commutator Refurbishing, Rebuilding, & Refilling

- Manufacturing High-Quality Custom Collector Rings

- EM Express – 24/7 Service Repair

From the rail industry to naval submarines and beyond, commutators built by Electric Materials are trusted for their exceptional quality, performance, longevity, mechanical, and electrical integrity.

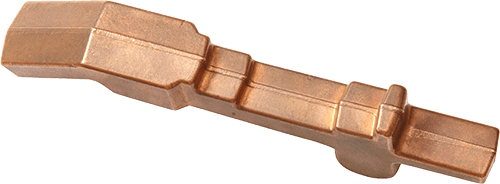

Copper Extrusion & Bronze Extrusion

As a U.S. specialty copper mill, our high quality extruded shapes, rods, and bars are produced from copper billets we cast in-house. As a leading U.S. copper forging manufacturer, EM carries an extensive tooling inventory consisting of several thousand dies. However, if custom tooling is necessary, you can rely on our seasoned toolmakers to produce all required extrusion and draw dies in-house. We can provide a material Certificate of Compliance with your shipment, or if requested, conduct full metal tests for a minimal charge. We welcome the opportunity to review your copper, high copper, brass, and bronze extrusion requirements.

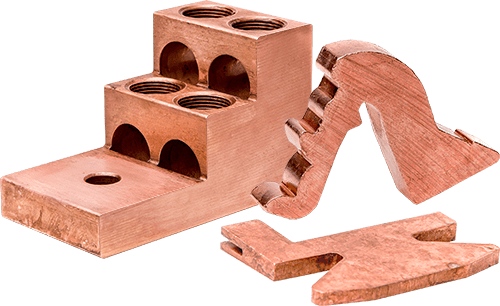

Sand, Centrifugal, and Permanent Mold Copper Casting Manufacturer

Electric Materials has specialized in copper casting, fabricating, and machining for a wide variety of industries over the past century. Some of the copper castings we provide are sand castings, centrifugal castings, and permanent mold castings. EM manufacturing and product development capabilities are key to achieving the most cost-effective products to meet customer requirements. No matter what the volume is, our staff is committed to your success by supplying high-quality castings. All castings are regularly inspected throughout the manufacturing process.

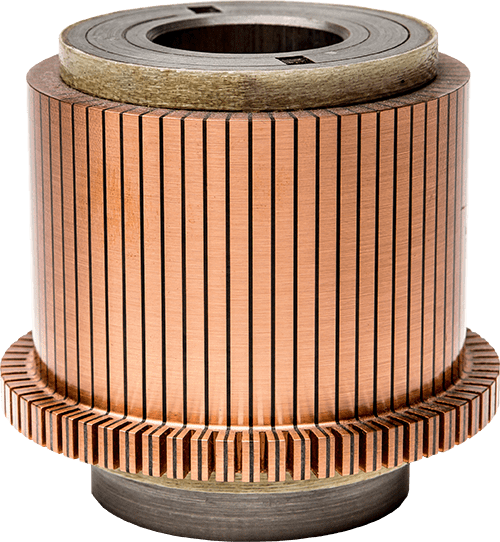

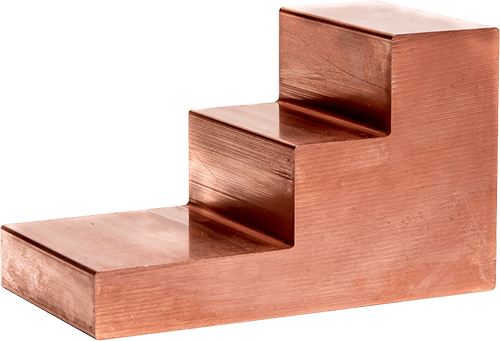

A U.S. Copper, Copper Alloy, Bronze, and Brass Forging Manufacturer

Electric Materials has been manufacturing quality copper forgings for over 100 years for a wide variety of industries including the electrical, transportation, and mining markets. With over 420,000 square feet of manufacturing space, our expertise in manufacturing high-quality forgings of high conductivity copper, chrome copper (conforming to RWMA Class II), and brass or bronze will meet your requirements.

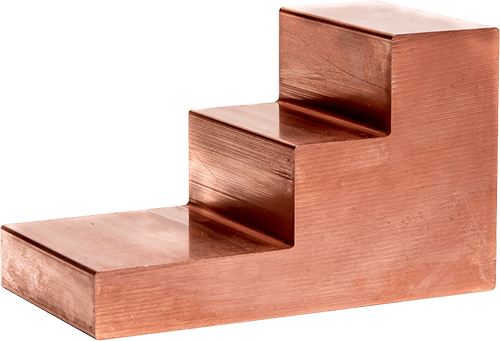

U.S. COPPER ALLOY MANUFACTURER & SUPPLIER For Data Center Power Distribution

Electric Materials is North America’s leading provider of data center power distribution systems. As the data center market expands, the need for U.S. power systems designed to meet those exacting demands are required. Electric Materials, a U.S. manufacturer and supplier, can provide custom copper extrusions, machining, and plating to meet the end client’s specific requirements. Nickel, silver, and tin plating can be applied to full-length extrusions.

Industries Served

Transportation

Oil and Gas

Mining

Nuclear

Nuclear Compliance ASME NQA-1

For customers involved in nuclear safety-related work, Electric Materials recently implemented and currently maintains an ASME NQA-1 (10CFR50 Appendix B) compliant quality assurance program. Electric Materials is an active member of Nuclear Industry Assessment Committee (NIAC). The following new instruments were purchased in QA to increase capabilities and improve the precision of our measurement results:

- PRATT & WHITNEY LABMASTER gage calibration instrument. This precision instrument is repeatable to within 1.6 microinches.

- BRUKER optical emission spectrometer. This instrument is capable of measuring 26 elements.

- FARO Arm (portable CMM). It is capable of accurately measuring up to 9 feet.

- Keyence IM-6000. This instrument is capable of accurately measuring 99 dimensions within 3 seconds.

24/7 Commutator Repair

When you need commutator repair in a hurry, take the TEMCO Express. We provide continuous service 24 hours a day, 365 days a year.