Data Centers Power Distribution Solutions

Primary & Backup Power Supply

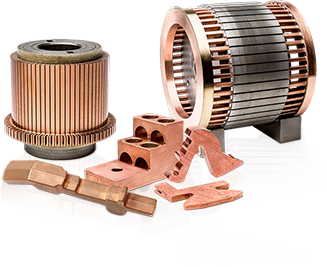

In today’s complex digital landscape, uninterrupted power is essential for data centers to maintain efficiency, security, and reliability. The Electric Materials Company is a key supplier for the data center power distribution systems. Our copper extrusions and castings ensure superior electrical conductivity, durability, and thermal management for primary power supply systems.

We provide the following copper products for Data Centers:

optimizing power

The Electric Materials Company’s solutions optimize power distribution, reduce losses, and enhance system stability. We deliver fully machined and plated parts to your specifications, every time! Our products are 100% USA-sourced and manufactured in our North East, PA facility.

Benefits of using Copper in Data Centers Power Supply

Copper plays a crucial role in ensuring efficient and reliable power distribution in data centers. Here’s why it’s the preferred material:

- High Electrical Conductivity

Known as the best conductor of electricity, copper provides minimal resistance, reducing energy loss and ensuring stable power transmission across data center systems. - Superior Heat Dissipation

Its excellent thermal conductivity helps manage heat efficiently, preventing overheating in high-density power environments. - Durability, Longevity & Sustainability

Copper resists corrosion and degradation, ensuring long-term performance with minimal maintenance. Additionally, copper is fully recyclable without any loss of its properties. We melt and recycle copper right here in our plant in North East, PA - Compact & Space-Efficient Design

Due to its high conductivity, copper wiring and components can be designed more compactly compared to alternatives like aluminum, optimizing data center layouts. - Enhanced Reliability

With its robust physical properties, copper helps maintain uninterrupted power supply, a critical factor for data center uptime and efficiency.

The Electric Materials Company:

Copper billet extrusion process

The Electric Materials Company:

Copper billet extrusion process

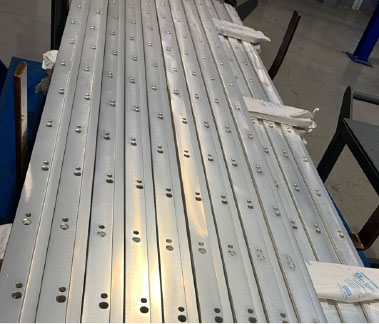

Overhead/interior power distribution busbar

Overhead and interior power distribution busbars are essential components in data center power supply systems, offering efficient and scalable solutions for managing electrical distribution, allowing circuits to be removed or added easily. The Electric Materials Company provides busbar for systems, designed for data centers.

Benefits of overhead power distribution busbars in Data Centers Power Supply

- Space Optimization

Overhead busbars free up valuable floor space, allowing for better airflow and equipment arrangement. - Scalability & Flexibility

Easily reconfigurable to accommodate growing power demands without extensive rewiring. - Improved Efficiency

Reduces power losses compared to traditional cable-based systems, ensuring stable power delivery. - Enhanced Safety

Minimizes the risk of electrical faults and arc flash incidents, improving overall system reliability.

- Thermal Efficiency

Excellent heat dissipation prevents overheating, ensuring stable operations

Custom shapes extruded to your specifications

In-rack power distribution

Power connection within server racks is essential for efficient power distribution in data centers, ensuring reliable and scalable energy transfer to servers and networking equipment while minimizing power loss.

Benefits of in-rack Power Supply

- Space-Saving Implementation

Compared to traditional cabling, our copper busbars provide compact, streamlined power delivery, maximizing rack space utilization - Longevity and reliability

Durable copper materials ensure corrosion resistance and long-term operational stability, reducing maintenance costs and downtime. - Customizable Designs

Manufactured to precise specifications, our copper components allow for tailored power distribution solutions that seamlessly integrate into different rack configurations. Our products are compliant with OCP HPR (High Power Rack) design requirements and ISO 9001 QA.

The Electric Materials Company:

Silver-over-nickel plated busbars for Data Centers and PDU

The Electric Materials Company:

Plating Bath

Supporting Products and Services

The Electric Materials Company is a vertically integrated Specialty Copper Mill with over eleven decades of metalworking know-how. We have engineering and production capabilities for a wide variety of custom and standard copper extrusions, shapes and fabricated components for various applications.

Plating

The Electric Materials Company’s metalworking processes are all done in-house under our ISO 9001 QA system. We offer the highest quality proprietary electrolytic silver-plating process for all copper busbars. Our hard-plated sliver over nickel is proven to meet the harshest standards for data center reliability and wear resistance.

We plate with these materials:

- Silver: up to 20’ in length

- Silver-over-nickel: up to 20’ in length

- Tin: up to 12’ in length

- Custom extrusions

- Fabrication

- Custom copper shapes

The Electric Materials Company has over 110 years of experience in extruding intricately designed shapes for a variety of customers to meet their needs in electrification. Our talented engineering team is available to assist with your

The Electric Materials Company has over 110 years of experience in extruding intricately designed shapes for a variety of customers to meet their needs in electrification.

The United Stars family of companies offers many additional products for Data Centers applications:

Company: United Industries

Product: High Performance Stainless Steel Tubing

Application: Direct-to-Chip Cooling solutions