U.S. Copper Alloys

A Leader in Copper Alloys Manufacturing & Processing

For over a century, Electric Materials has been recognized as a leader in the manufacturing and supply of copper alloys. Founded in 1915 as “Copper Works,” EM has evolved into a complex manufacturing company of copper components for a wide variety of industries, including the electrical, mining, and transportation markets. Working from a manufacturing facility that covers 420,000 square feet, EM is a multifaceted organization with six separate production departments. Our areas of expertise include:

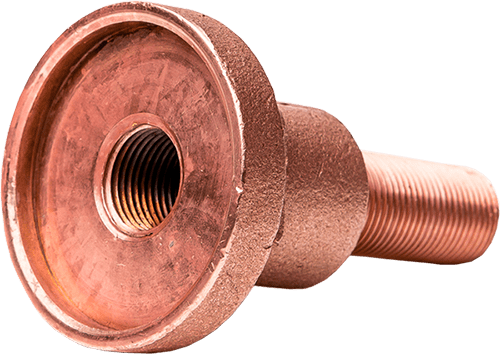

- Semi-continuous casting, sand, and permanent mold casting (Die Casting)

- Underwater extrusion

- Forging

- Finish machining

- Electroplating

- Commutator and AC Rotor manufacturing

Wrought Copper Alloys for Rods, Bars, and Specialty Extrusions

Electric Material’s specialized mills work with 24 wrought copper alloys to regularly produce high-quality rods, bars, and extrusions. These products are available in an unlimited variety of shapes, sizes, and lengths (copper alloy cold rolling, stamping, punching, and other services are also available).

As a fully integrated copper mill, our process begins with copper billet production. Prior to pouring, our metallurgical laboratory analyzes the chemical composition for adherence to established standards. Alloy properties are checked again at regular intervals throughout the mill process per our in-house quality assurance program, in coordination with our established ISO-9001:2015 quality control system. Our vertical integration enables us to produce highly engineered copper components from billet production through the extrusion and cold working processes. We then provide finish machining and electroplating as required. In-house tool design and manufacturing ensures rapid service and enables design changes to be implemented quickly. These unique turnkey capabilities keep all operations in-house and increase product throughput, improve quality, and reduce overall product costs.

EM’s four families of wrought copper alloys:

Copper and High Copper Alloys

Copper Nickel Alloys

| UNS No. | Common Name | Typical Applications |

|---|---|---|

| C70100 | EM Special Copper Nickel Alloy | Electronic beam welding of rotor bars and end rings |

Brass Alloys

Bronze Alloys

Cast Copper Alloys

Custom Sand Casting & Permanent Mold Casting

As a custom copper alloys manufacturer, processor, and supplier, Electric Materials (EM) specializes in both sand casting and permanent mold casting. Our high-conductivity copper alloys are available for a wide variety of electrical and mechanical applications. Desirable properties include excellent thermal and electrical conductivity, high resistance to corrosion, and good mechanical strength. Our extensive history as a copper alloy supplier allows us to easily handle small and large volume orders with parts weighing a few ounces up to 600 pounds.